First a little background. Fifteen years ago we cobbled together a simple open shed for temporary use. We needed a place to stash stuff out of the weather. We had cut down a bunch of ohia trees in order to open up an area for the solar panels, so we had all those poles and opted to use them for the roughly built shelter. We figured on using this shed for 2, perhaps 3 years at most, therefore we used the poles green (freshly cut) and didn't bother to debark them. Nor did we set them on a foundation of any sort. They sat right on the ground.

Then life happened, and we never did anything about making a proper open shed. We continued to use this one. It's absolutely amazing that it lasted 15 years!

In the last storm which dumped 7 inches of rain and blew some serious windy gusts, several of the upright support poles gave up the ghost and snapped. They were so dry rotted that I'm puzzled that they hadn't broken earlier. Not just little sections here and there, but the entire lower half of all the poles were dry rotted right through. Sitting right in the ground had allowed both moisture and fungus to creep up the poles.

I took a before photo of the damage in order to show you, but I accidently deleted it. But things looked bad. Just imagine 5 of the poles in the front were snapped off at various heights, plus one in the back corner. The roof never fully collapsed but it sure was a wavy, wonky mess. When I came out one morning and saw the damage, my immediate task was to get the dogs out from under the collapsing roof. They have a 10' x 30' kennel pen there. Next was to remove the equipment that I could.

Hubby was all for pulling out the remaining poles and bringing the whole mess down. David took a look, checked all the horizontal poles and found them to be sound. He suggested replacing all the upright poles with 4"x4"s, thus saving the structure. I gave him the go ahead to try.

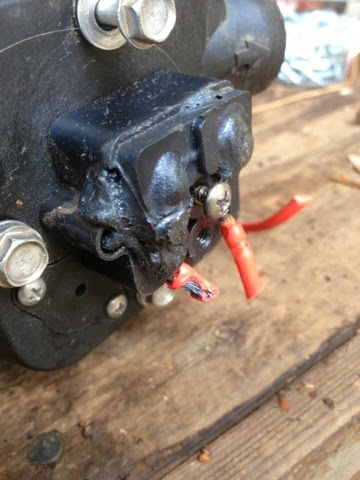

First task was to brace things so that it didn't totally collapse. Next was to acquire a bunch of 4"x4"s. Then by using two hydraulic jacks, David coaxed the roof up one spot at a time, replacing the upright poles, this time making sure that they rested atop concrete.

Amazing. He made it look easy and simple.

|

| Using just two of these jacks, David was able to jack up and support the roof while replacing each upright pole. |

Amazing. He made it look easy and simple.